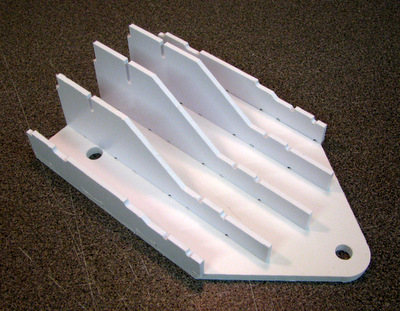

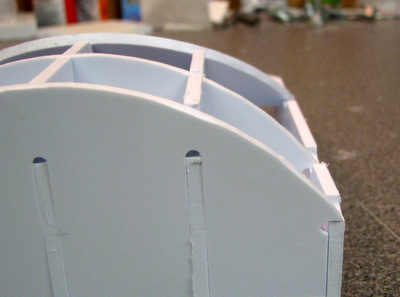

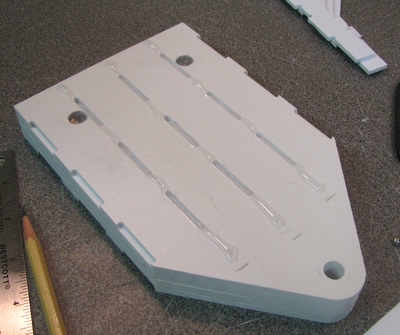

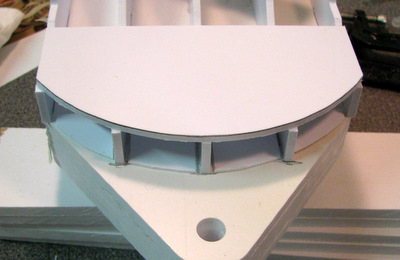

Dry fit the ribs and rings to get a feel for the fit |

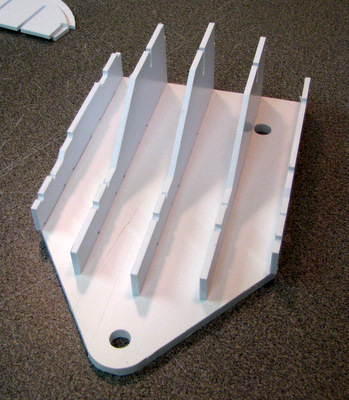

Mark the location of the ends of the ribs. Draw glue lines. |

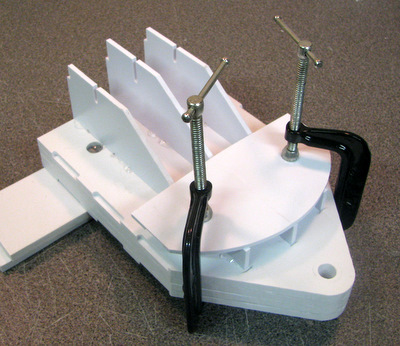

Apply Glue. |

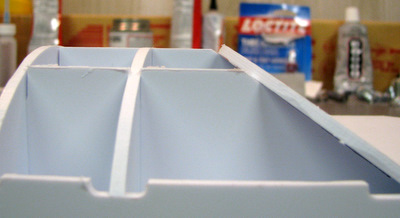

Use the curved shelf to clamp the ribs in place. |

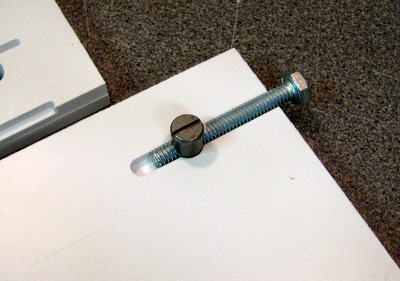

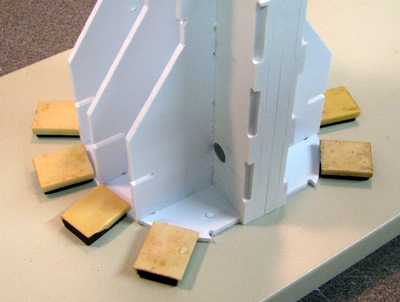

I used magnets on a steel plate to hold the end ring in place. Tape will also work !

Right: draw glue lines for the center rib

|  |

Glue and tape in place while the glue dries. |

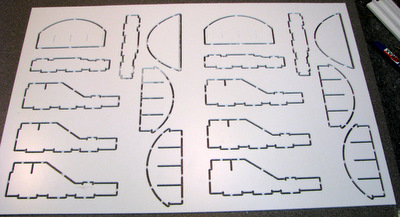

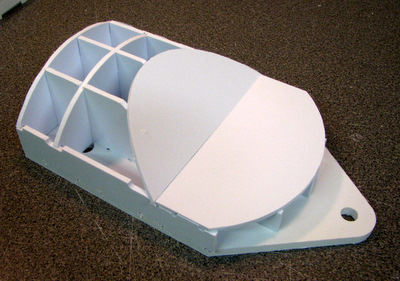

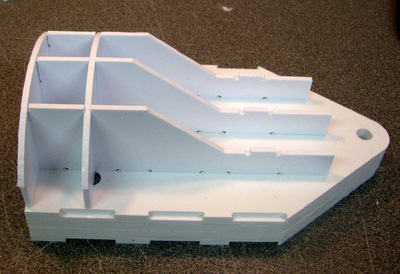

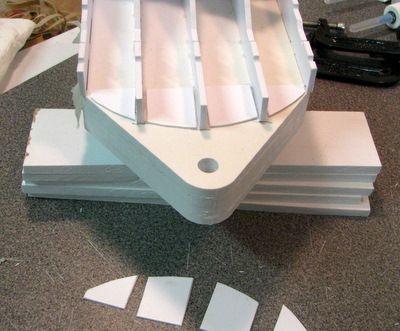

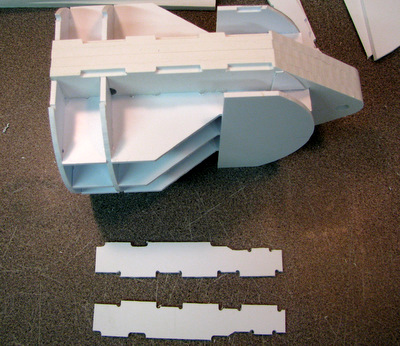

These parts from the skin sheet will be used to provide a bottom 'edge' for the curved skin to hold onto. |

|

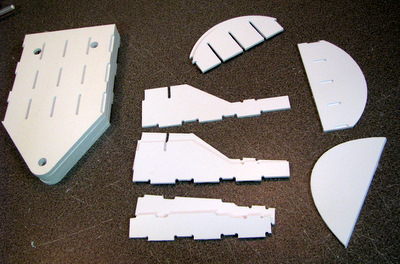

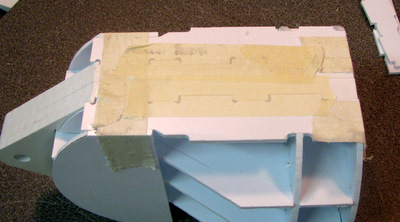

Use

the curved shelf to align the parts then glue in position. A smart

builder would have traced a line using the shelf BEFORE the ribs were

glued in place. |

|

Left: locate and test fit the edge pieces.

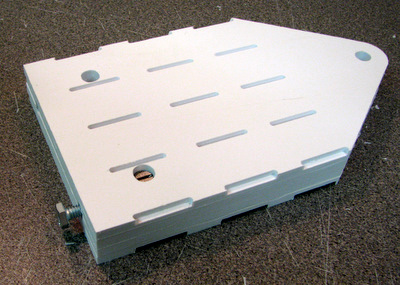

Above: Apply glue, and tape in place till the glue sets. |

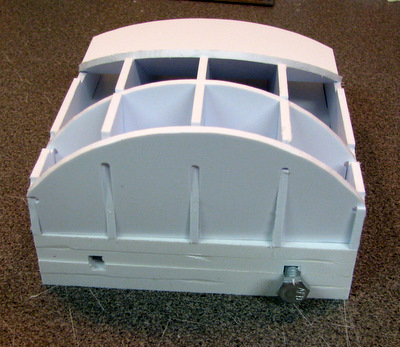

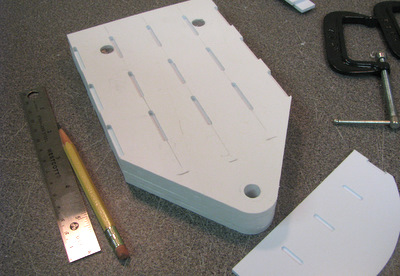

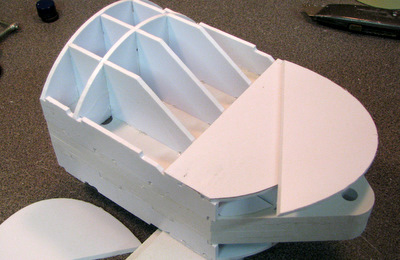

The last piece to go into place is the angled end piece. |

It's slightly wider than the ankle. Center it when you glue it. |