Tabs and Flash

First step is to separate all of the parts from the sheets they were machined from and remove the tabs and flash, if any.

What are Tabs and Flash?

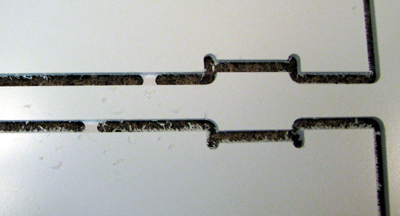

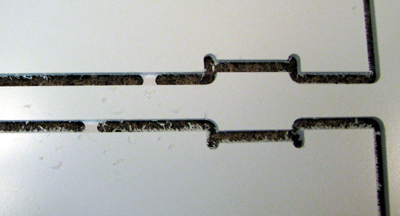

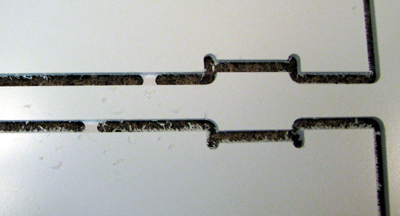

Tabs:

In

order to keep the parts in position while they are being machined small

tabs, typically .04 thick and about .25 long, are left in place to

prevent the cutting bit from throwing what would otherwise be loose

parts around the room.

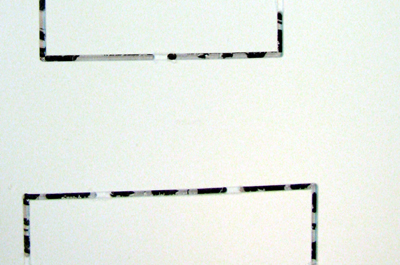

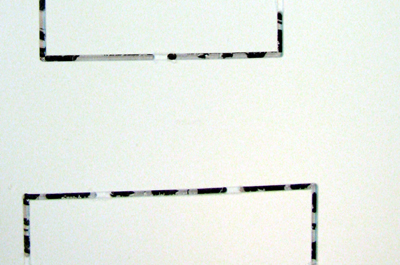

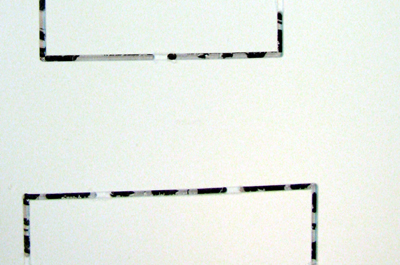

Flash: The name is taken from plastic PC

models which typically have "Molding Flash". Caused if the molds the

parts were made from didn't fit together precisely, small amounts of

thin plastic would be present along the joints. The same thing happens

to the parts I cut if the cutter doesn't go all the way threw the

material. Can be caused by minor differences in material thickness or

the cutting surface not being held flat.

Tabs |

Tabs and Flash |