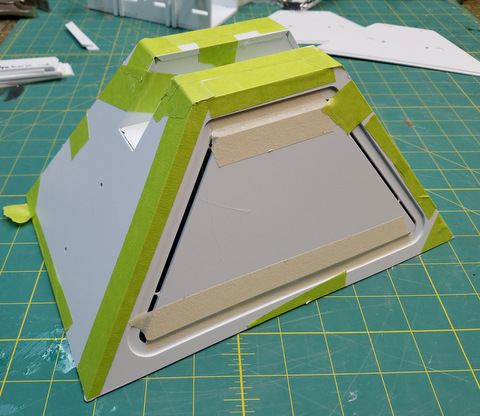

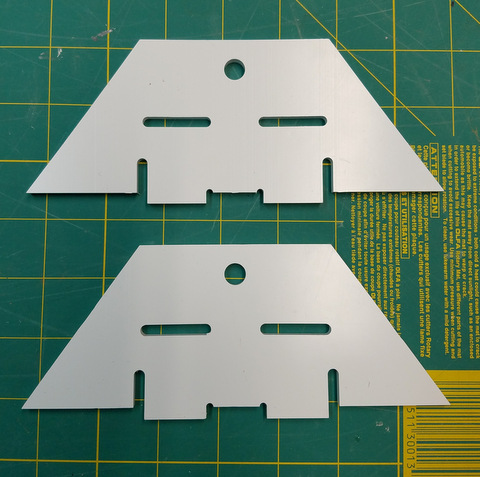

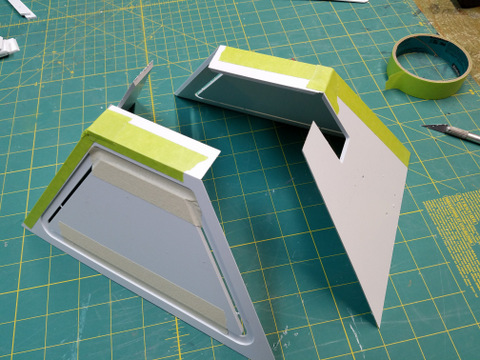

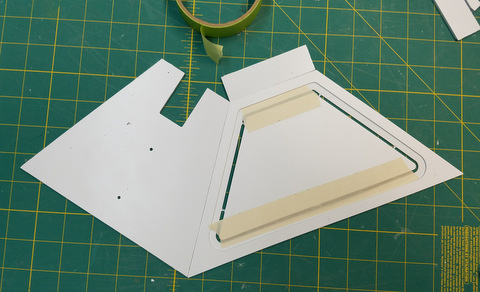

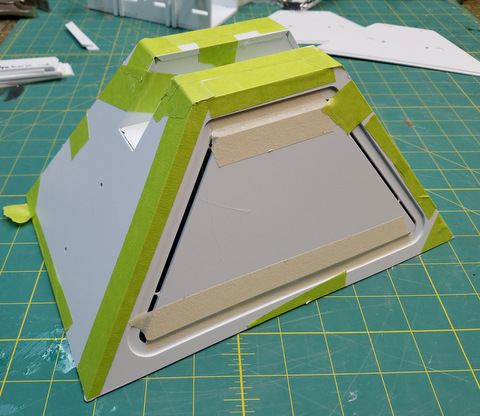

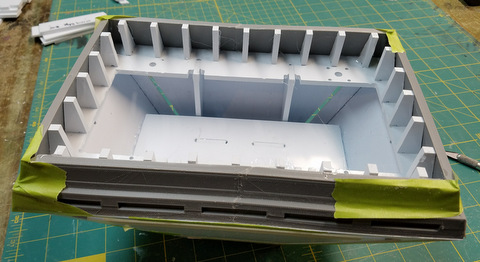

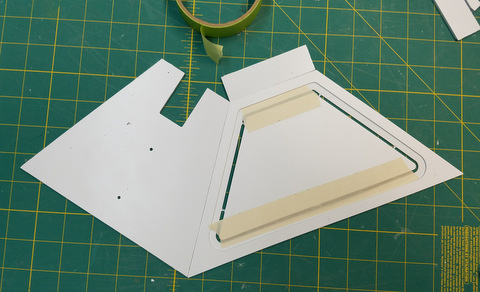

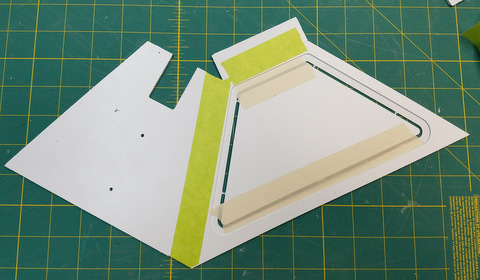

Tape the center section of the side panels

in place to improve the rigidity of the panel |

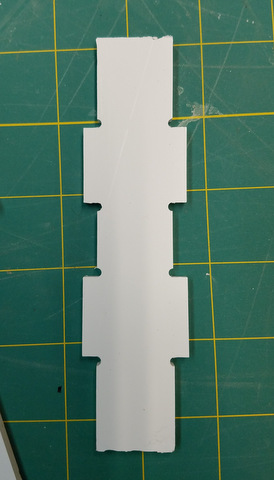

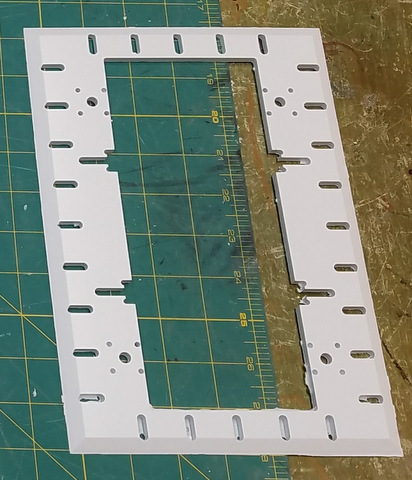

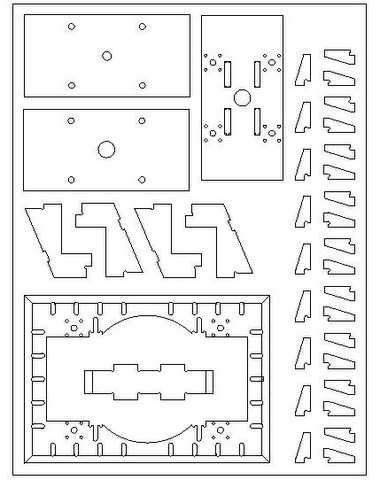

Place the

panels on a flat surface,

bevels down, and tape the edges. Make

sure the top

and bottom corners line up.

|

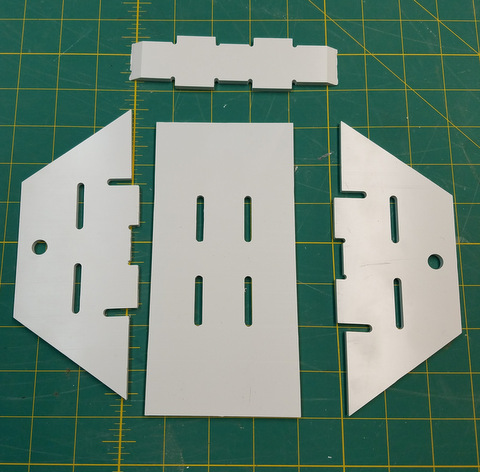

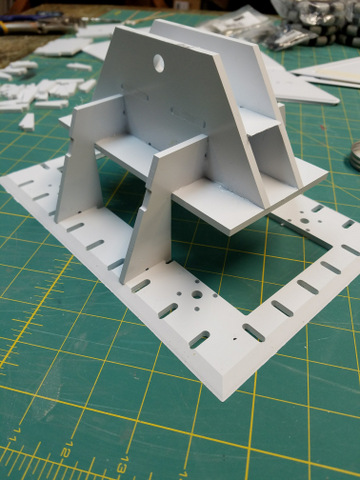

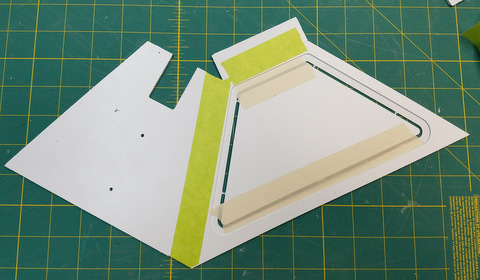

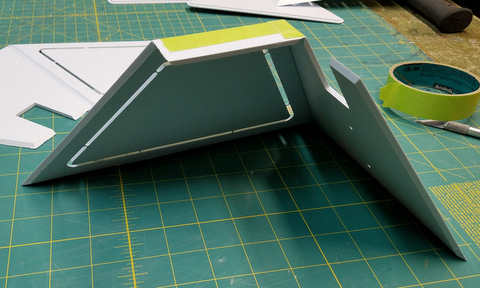

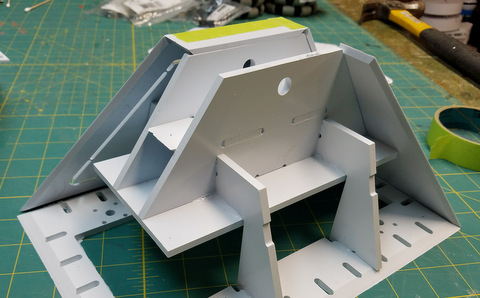

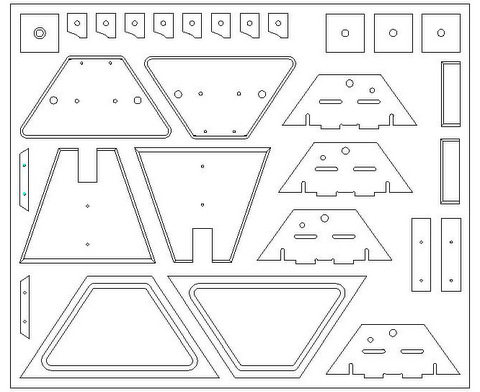

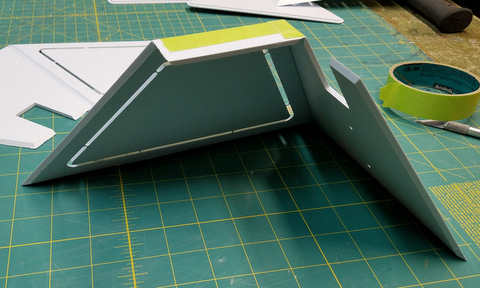

Then

fold the pieces in together to make half of the pyramid shape. Fold the

Top Strip down and tape. Right: repeat the process

for the other half shell Right: repeat the process

for the other half shell |

|

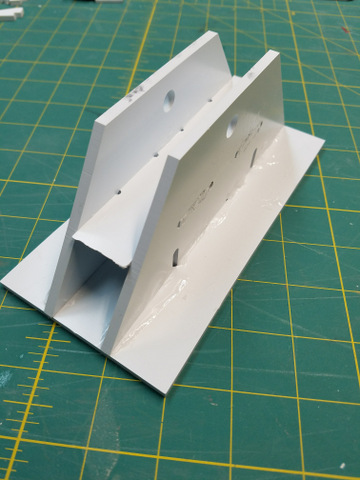

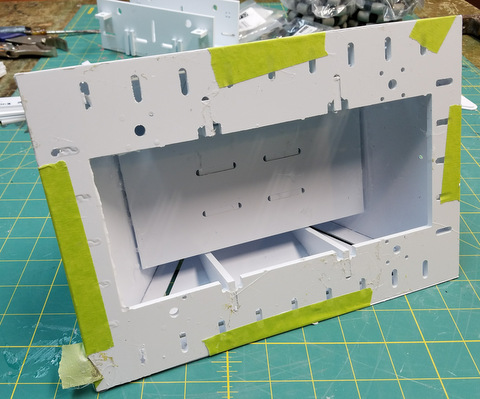

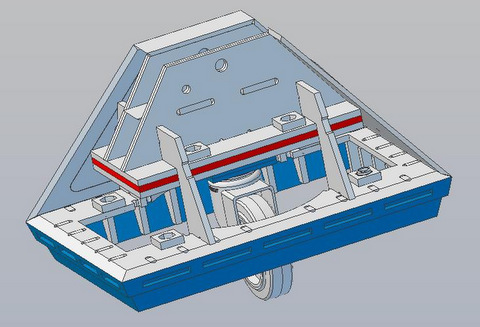

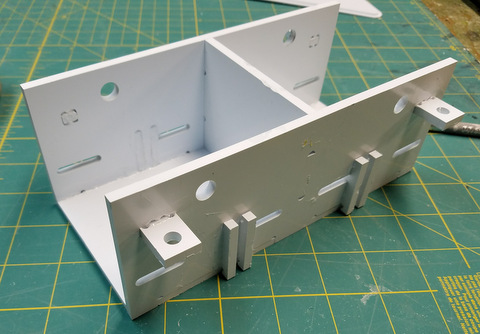

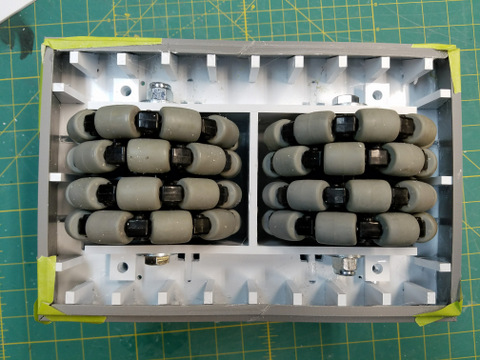

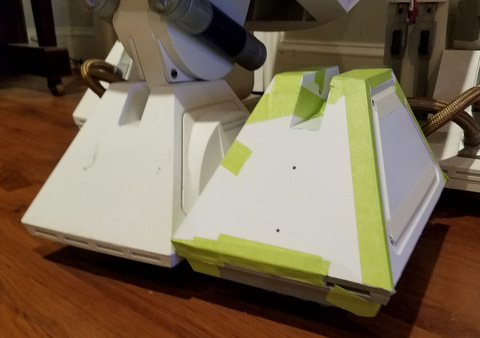

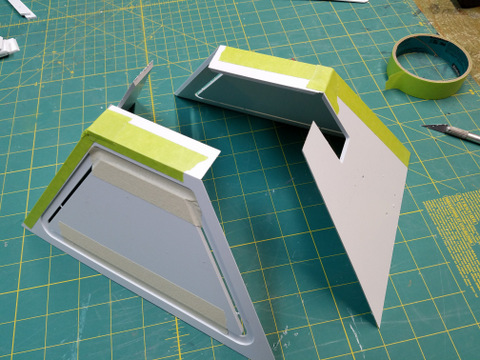

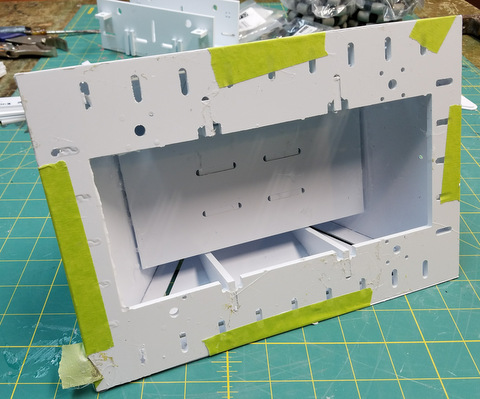

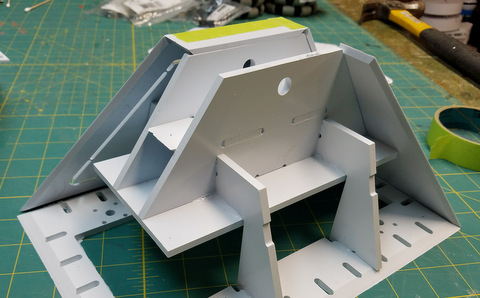

With the panels

taped together, it's time to do a test

fitting to see how the foot shell fits over the structural frame.

Right: Make adjustments in the structural frame for fit. Tape the two

half shells together around the frame once you are happy with the fit. |

|

|

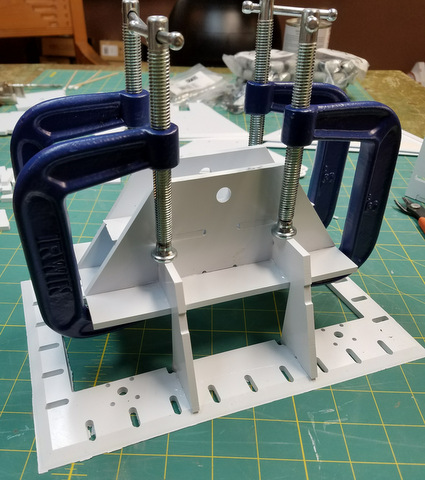

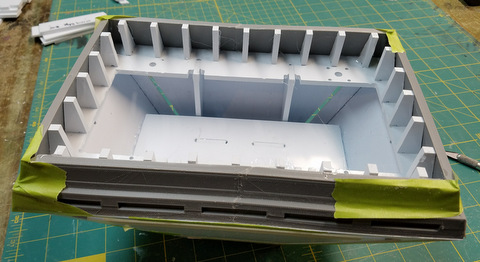

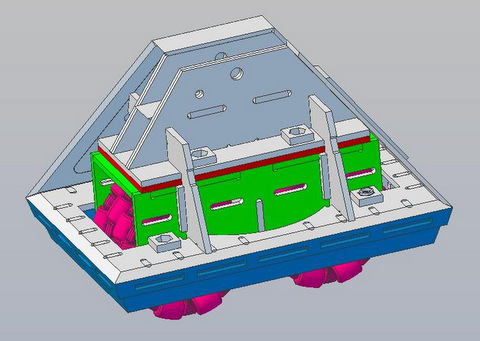

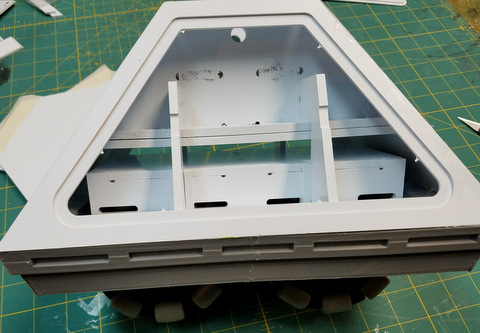

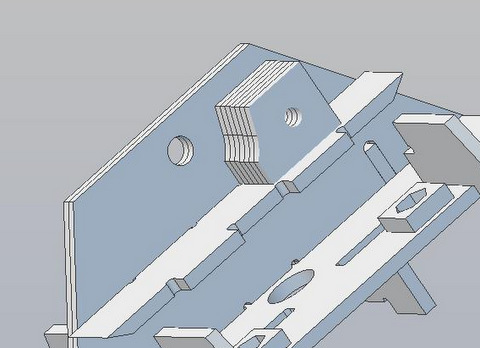

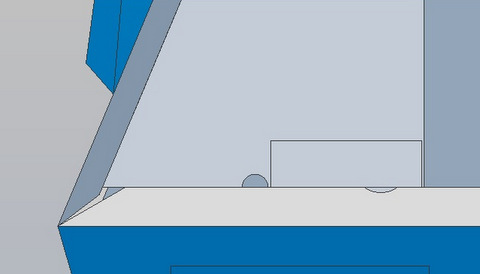

Turn the frame on

it's side and glue the shell to the frame. You won't be able to reach

all the areas that need to be glued yet.

DO NOT GLUE THE CENTER

SECTIONS OF THE SIDE PANELS!

Once the initial glue joints have dried, remove the tape holding the

center sections of the side panels in place. Those openings will give

you access to the rest of the shell's glue joints. Do a second pass

gluing the shell to the frame.

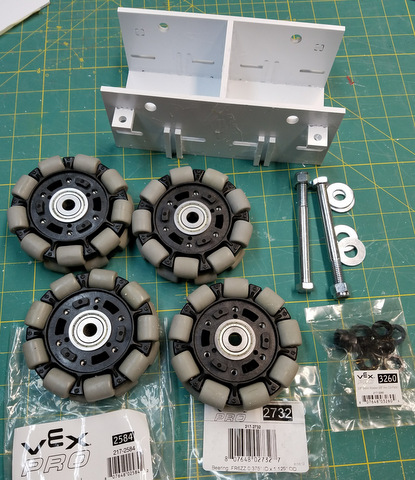

Next, once the glue joints are dry, we

will add the apron braces and

the apron parts to the bottom of the shell

|

|

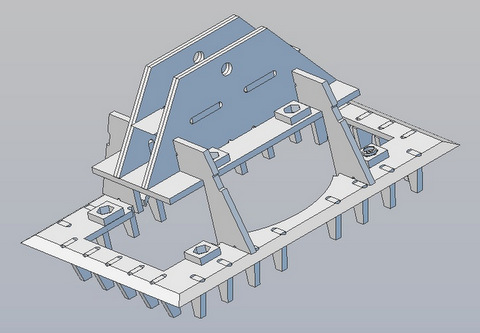

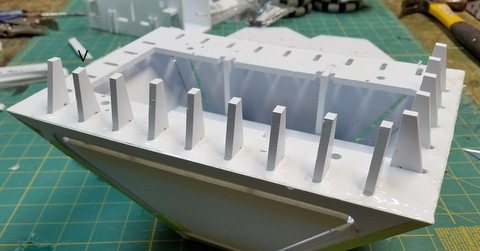

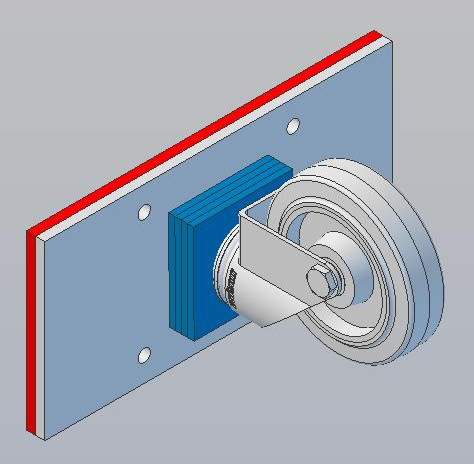

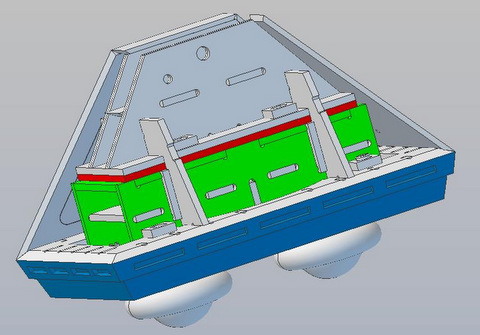

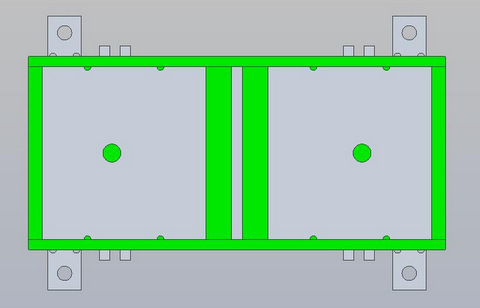

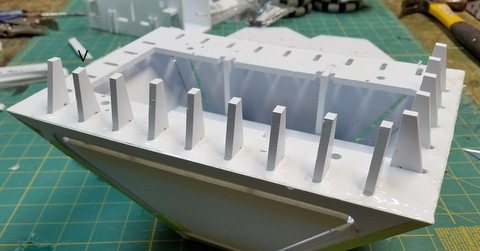

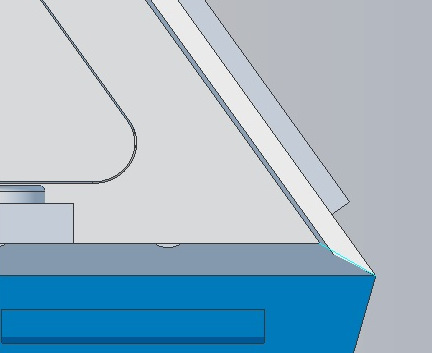

The Apron

Braces are designed to offer more support to the apron pieces than the

previous center foot design. They also provide an anchor to clamp the

apron parts to.

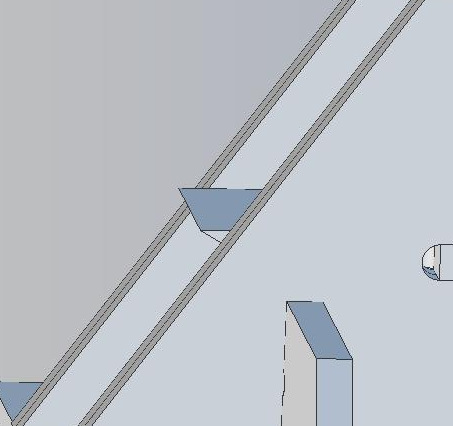

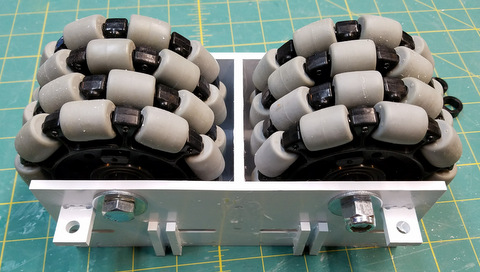

The Bottom Plate is also a solid surface in this design. The previous

design had needed putty to fill the void between the Shell and the

Bottom Plate.

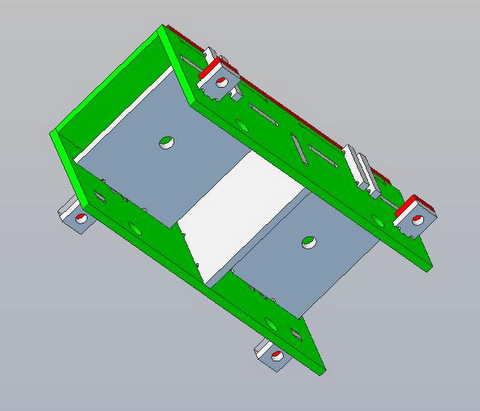

Note: make sure the brace pieces are lined up. The inside edges of the

braces should be vertical. Note the brace marked in the pix is out of

line.

|

|

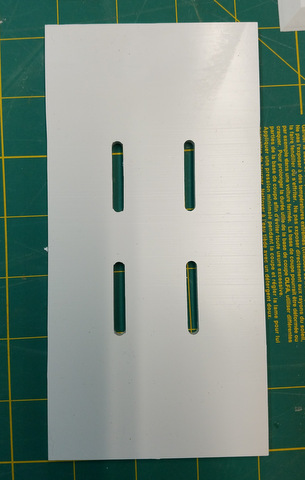

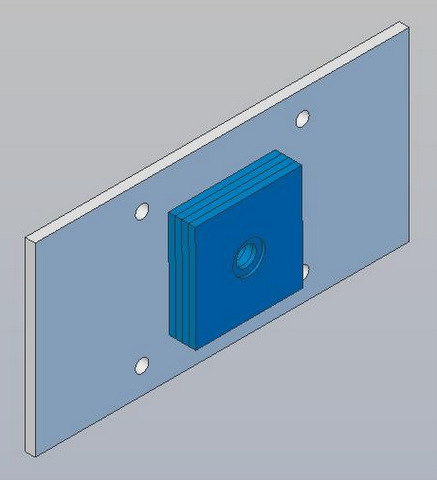

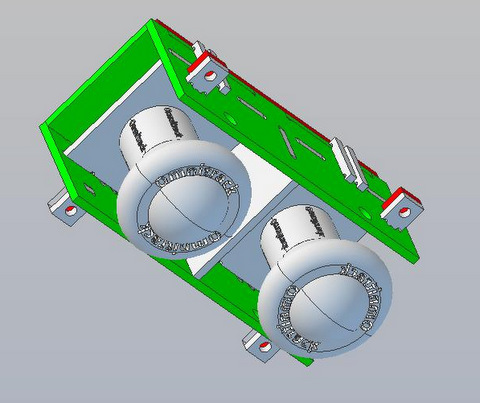

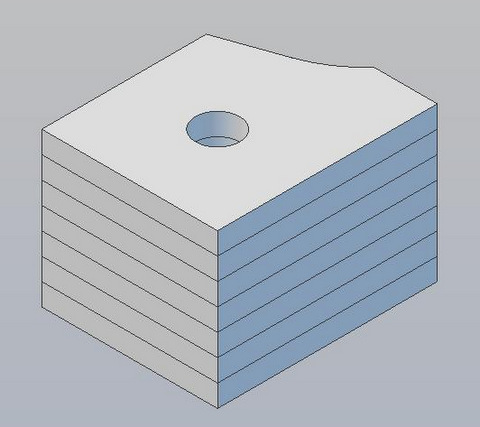

Apply the 3D

printed Apron trim parts to the Bottom Plate.

Note: Apron Braces are now cut shorter than the Apron to eliminate the

need to file them lower so they don't show.

Depending on how your Apron was printed you may want

to reinforce the corners by filling in the corner voids with an epoxy

cement or similar product.

|

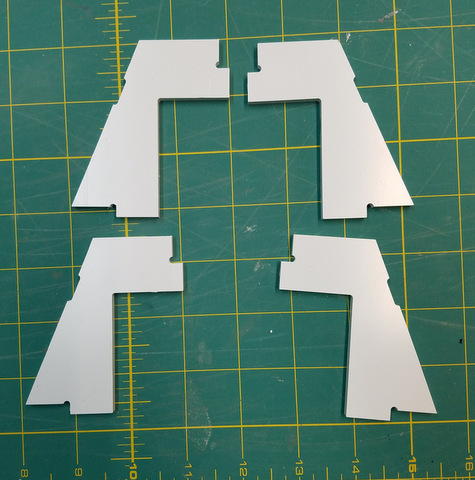

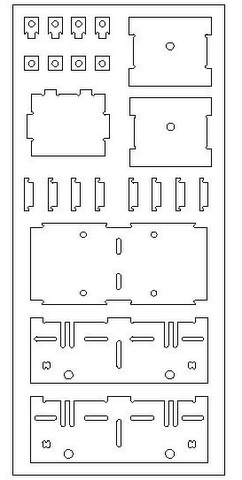

Assemble the

second half shell the same way.

Assemble the

second half shell the same way.