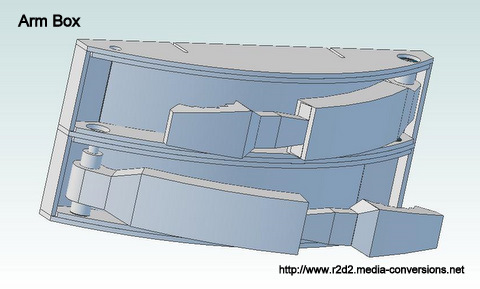

Click on the image for a 3D .pdf version.

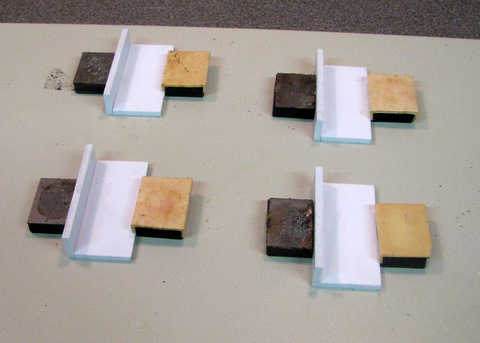

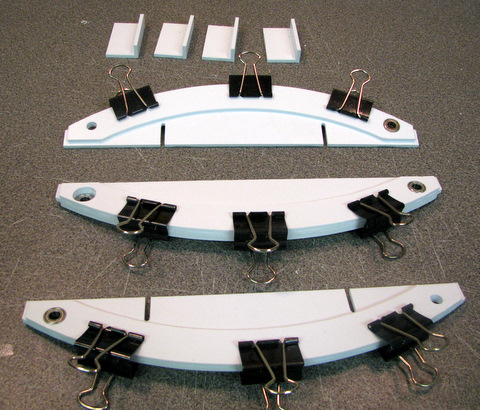

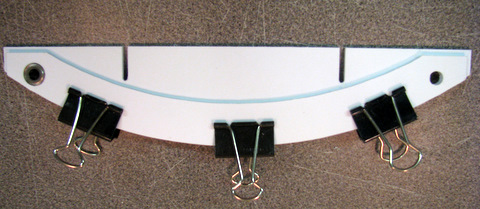

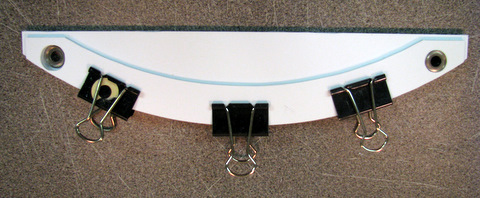

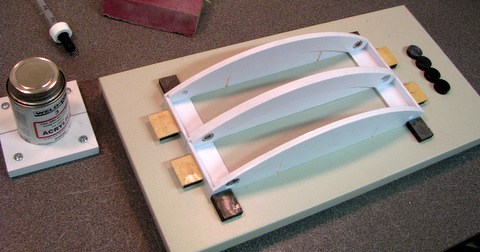

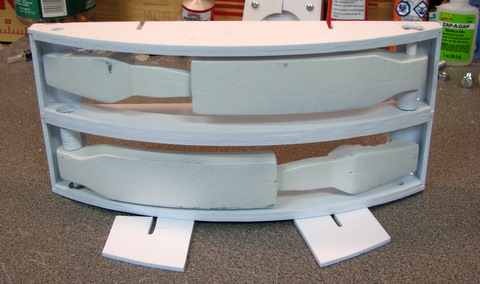

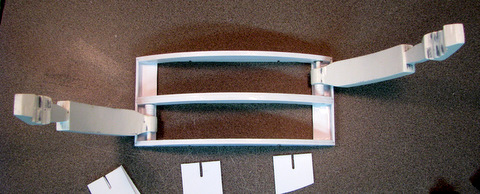

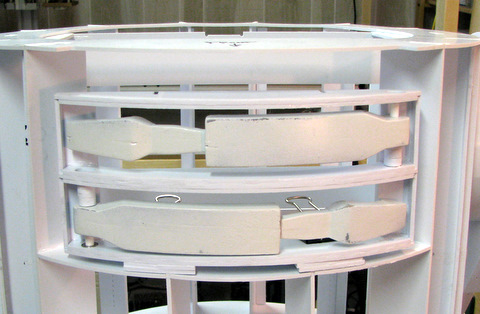

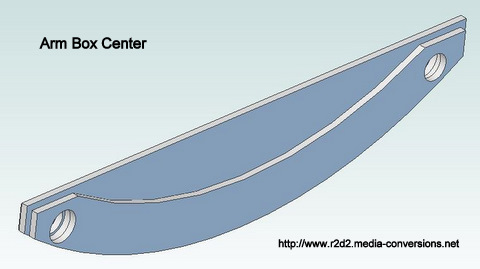

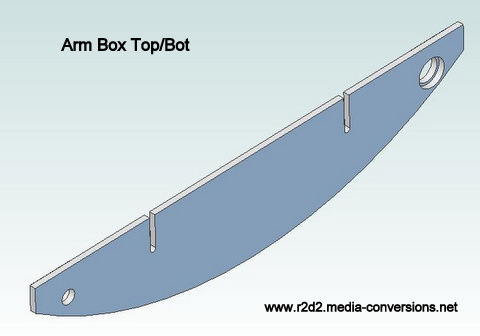

These are the Center and Top/Bot parts to the Arm Box without the bearings. They are linked to 3D .pdf files so you can see how the flanged bearings fit.

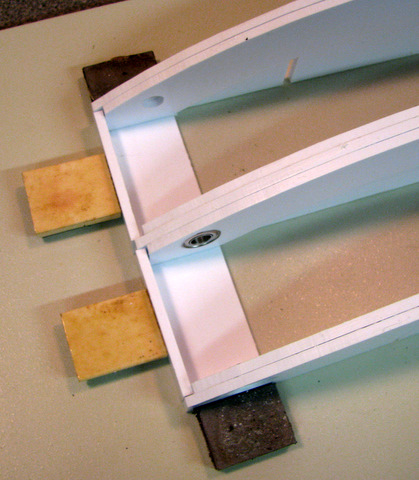

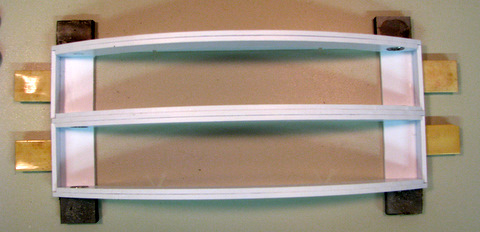

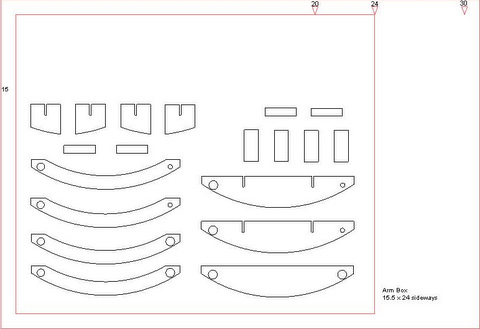

The outside top/bottom sections have the slots. Their mating inner top/bot pieces have matching small holes (for screwdriver access).

The Inside Middle section has no slots and two large holes. The mating inner pieces have one hole larger than the other. When you assemble the stack make sure the smaller holes are on opposite ends.

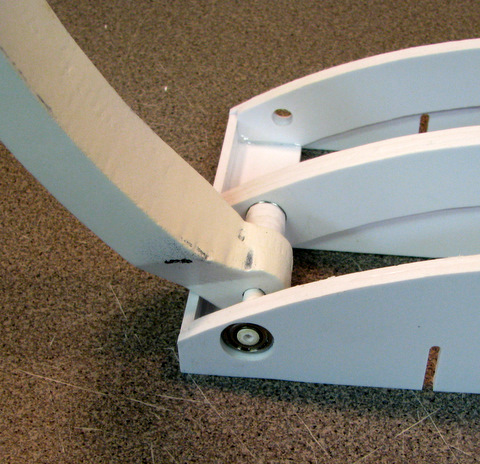

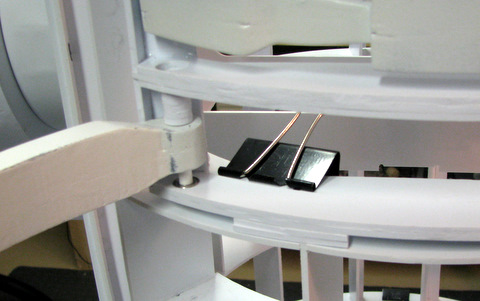

Plastic Tube - used as shaft - .25 OD x .125 ID x 2.25 long - 2 pcs - Plastruct #90106 or equiv

Using a plastic tube instead of a .25 metal shaft allows you to anchor the tube in place by putting a small screw in the end.

Flanged Bearing - .25 ID x .5 OD - type fr188zz (the zz means they are shielded, you don't really need the shield). Strictly speaking you could use a bushing instead of a bearing as this is not a heavy duty application so get any kind of fr188 bearing.

While VXB is the source almost everyone thinks of first but at about $5/bearing they are not a low cost supplier.

Boca Bearing was offering a 10 pack SKU: #99FR188-ZZ-X10 for $12

Boca was also on Amazon so check there, and as usual, also run a search on Ebay (you might get free shipping from either one!)