Eggcrate and

Tab & Slot Design

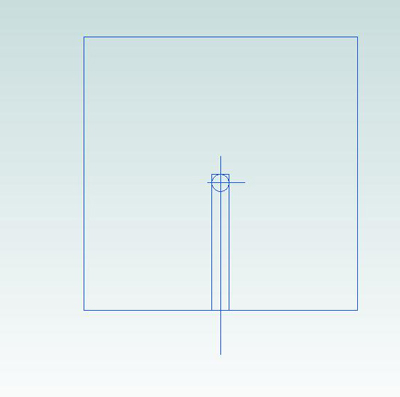

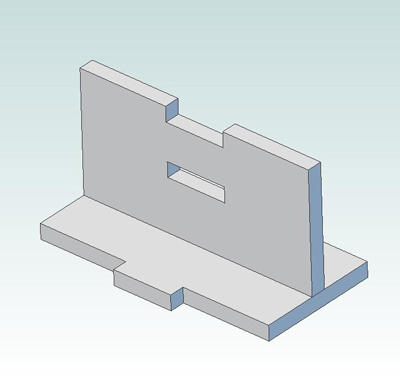

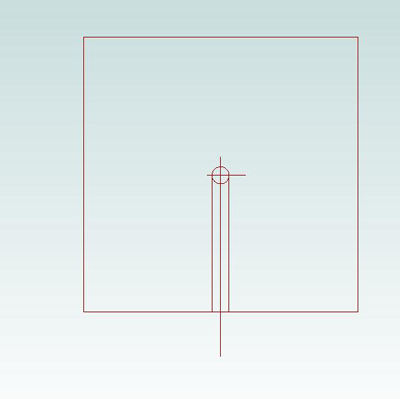

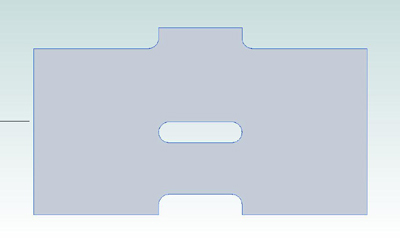

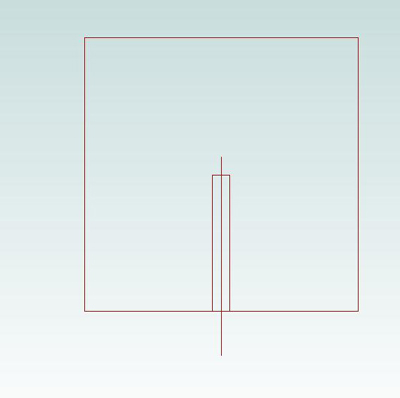

Eggcrates, the interlocking cardboard

dividers in boxes used to keep the contents from rattling around, have

been around for a long time. When you go to design them into parts you

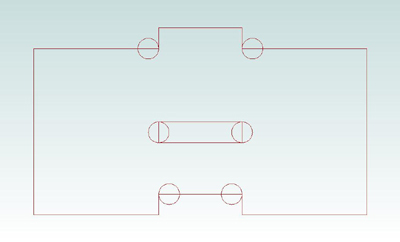

have a dilemma. Do you show them with square cut edges in the slots or

with rounded edges? It's easier to show a square cut and the 3d parts

are easy to create and 'mate' easily in the design package I'm using

(Alibre Design).

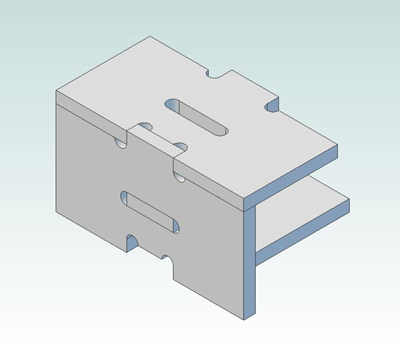

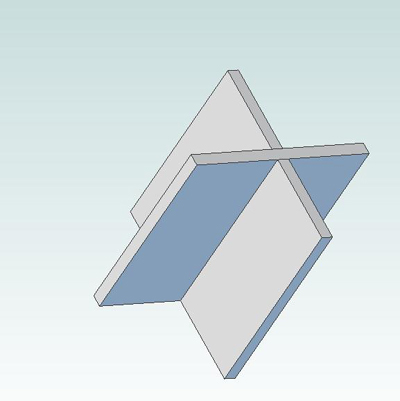

typical slot typical slot |  resulting mated 3d parts resulting mated 3d parts |

No matter what you do the cutting bit is going to leave a rounded profile.

If you cut on the part profile then the slot will stop at the bottom of

the cut but the parts won't mate completely because the parts will not

seat. |

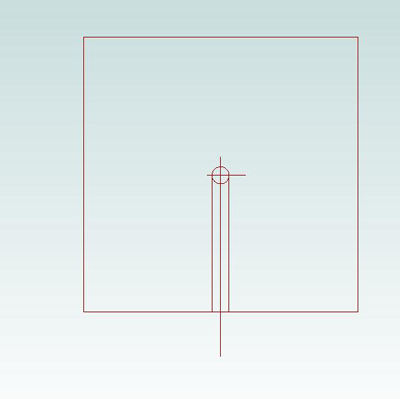

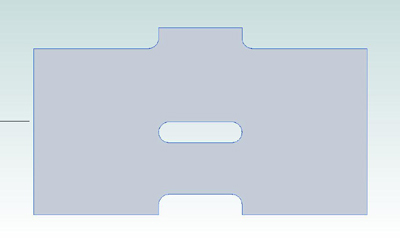

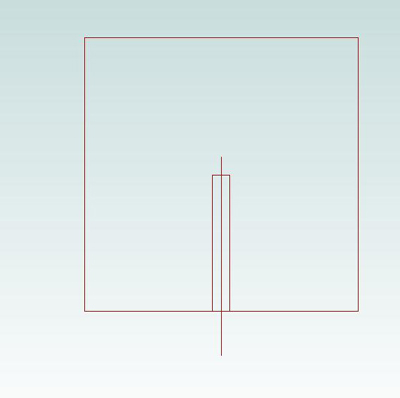

There are a number of possible solutions. One is to show the part with a rounded

bottom (called a fillet). The slot then goes full depth and can be cut as part of what's usually called a profile cut. |

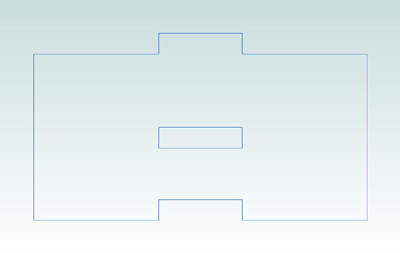

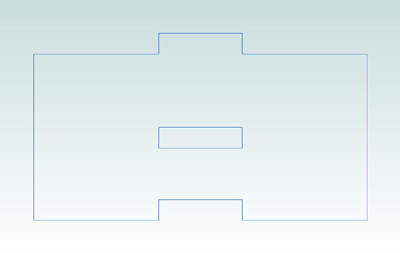

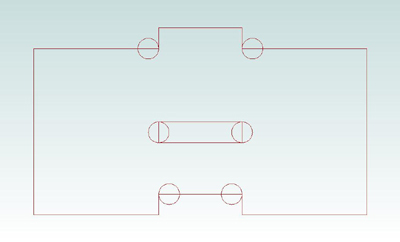

Tab

and Slots, as "insert tab A into slot B", have also been around

forever. Again the dilemma is how to show them and how to machine them.

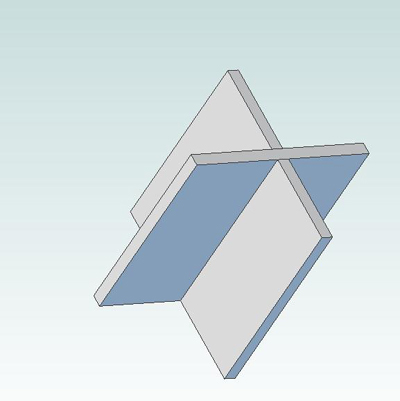

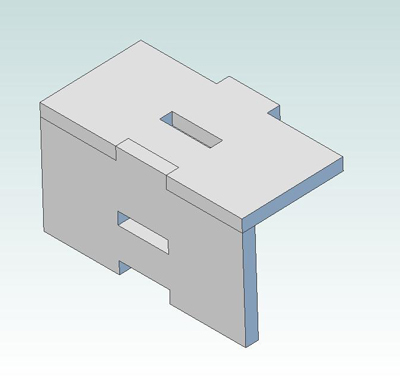

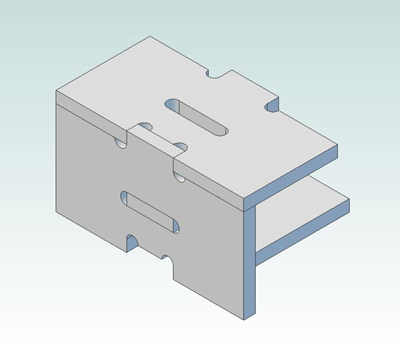

| Here's a sample part with both tabs and slots shown as square edged.

Below we show 3d versions of the part with both edge and mid-part matings.

The problem is, of course, like the eggcrate slots, you can't machine the square edge.

|

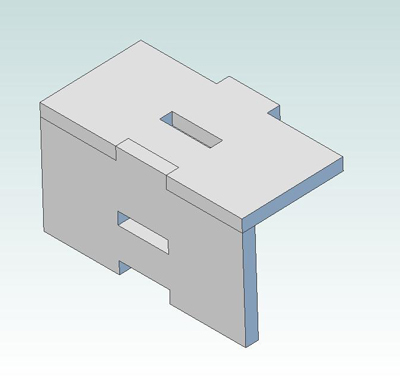

|  |

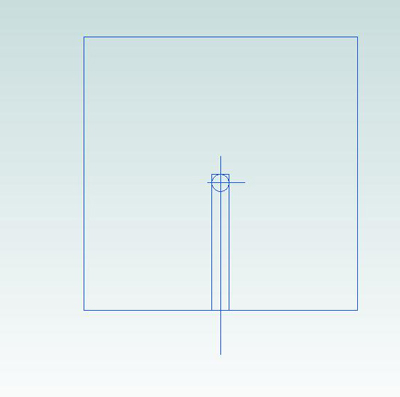

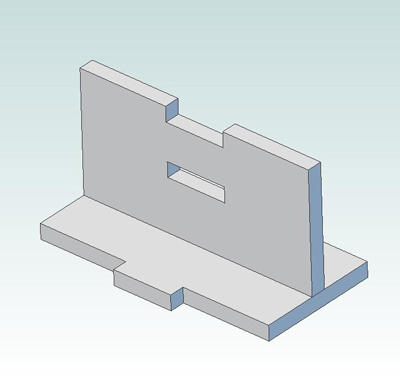

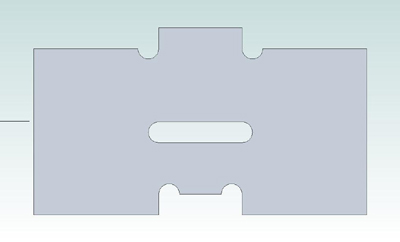

| To the left is what happens if you machine the profile above.

The parts won't mate because the rounded edged interfere.

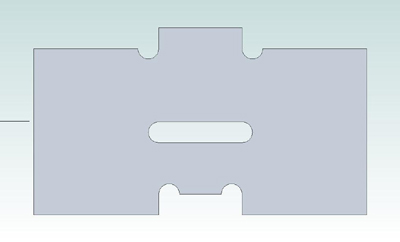

Below is a typical solutions which adds fillets to the profile to create the

necessary relief. |

|  |

| There are consequences to using a Tab & Slot design.

If

the edges, or surface, where the Tab & Slot come together are

exposed then the fillet cuts will have to be filled. Since there are

typically other construction issues that require filling in this is

typically not an issue.

One alternative, of course, would be to nc

machine the parts without the fillet cuts and then use a file to square

off the edges by hand. |

typical slot

typical slot resulting mated 3d parts

resulting mated 3d parts